Intra Trade Africa Tungsten Weld

Tungsten Weld

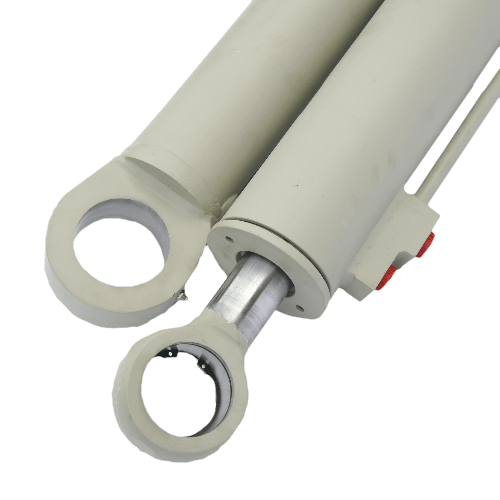

We use a co2 welding process for our Tungsten Hard face welding applications. During the welding process tungsten particles are fed into melting pool by a vibration hopper. We have a fine and a course tungsten weld with tungsten particles starting form 0.5mm up to 2mm in size. A wear resistance welding wire are used to ensure a hard matrix with the tungsten that has proven to outlast most available wear resistance materials available on the market.

Fine Tungsten weld:

This is a CO2 welding process where the Fine Tungsten Is deposited into the melt pool of the welding wire.

The Tungsten particles are between 0.3 – 1mm in size.

Welding deposit height 3-4mm high.

The Fine weld is most commonly used in the Grinding, Crushing and farming industries.

Most affective on fine materials less than 40mm in diameter.

Course Tungsten weld:

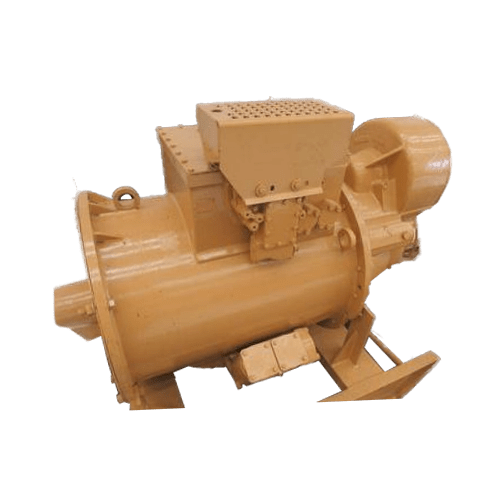

This is a CO2 welding process where the Course Tungsten is deposited into the melt pool of the welding wire. The Tungsten particles are between 1 – 1.6mm in size Welding deposit height 4-6mm high with tungsten protruding from weld. This weld is used when good resistance to abrasion and impact in dry or wet environment is required. Example GET, Bucket teeth, Cutting edges, Mixing paddles, Grizzly Bars, Dragline Buckets etc.

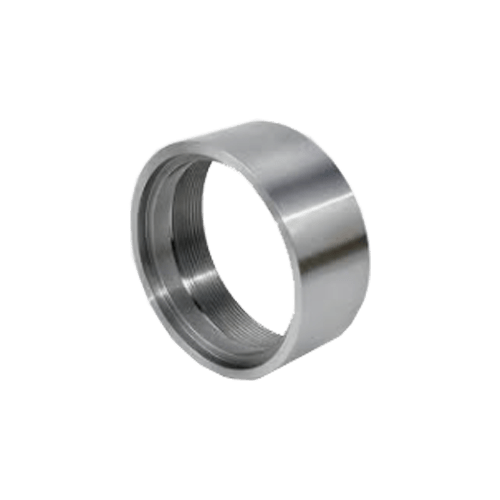

Fine Tungsten Grit application: (1x2 Tung Grit)

This is a Brazing process where the pre-manufactured Tung Grit Rods are brazed onto raw material. The Fine Tung Grit Rod consists of Tungsten Particles 1 – 1.6mm in size and a Copper alloy. These Rods are most commonly used for most mixing tools. (Cement, pelletising, Slurry, Sand) Screw Feeders, Drilling Stabilizers. Most effective on smaller materials. This is a good product for onsite repairs. These rods are available in 5kg bundles.

Coarse Grit Tungsten application: (2x4 Tung Grit)

This is a Brazing process where the pre-manufactured Tung Grit Rods are brazed onto raw material. The Coarse Tung Grit Rods consist of Tungsten Particles 2-5.5mm in size and a copper alloy. These Rods are most commonly used for most mixing tools. (Cement, pelletising, Slurry, Sand) Screw Feeders, Drilling Stabilizers. Most effective on bigger materials. This is a good product for onsite repairs. These rods are available in 5kg bundles.

Tung Genia Coating:

This is a specialized ultra-fine brazing application with round tungsten particles. This application is commonly used in sliding abrasion and applications that require a smooth lining. These rods are available in 15kg rolls.

Intra Trade Africa (Pty) Ltd

- VAT no: 4790294260

ISO Ratings

Copyright © Intra Trade Africa 2021 – All Rights Reserved | Privacy Policy